As a global technology leader, WINDHOFF stands for innovation, quality and reliability in the fields of rail vehicles, railway technology, shunting technology and track construction technology. For over 130 years, we have been developing and producing solutions in Germany that are used worldwide in depots and for infrastructure maintenance. Our drive is to increase efficiency and safety for our customers through continuous development and innovative technologies. In doing so, we rely on modular platform and building block systems that are convincing even under the toughest conditions.

WINDHOFF stands for innovation in rail transport worldwide. Our modular systems are the key to efficient personnel and material transport, precise work on rails and overhead lines as well as complex shunting and track construction projects.

In railway workshops around the world, we ensure smooth processes and maximum reliability. With many years of experience and the necessary foresight, we take on every challenge - and make your mission ours.

We rely on modular platform and modular systems to offer our customers maximum efficiency and flexibility - even under the toughest conditions.

We support our products throughout their entire life cycle - from development to maintenance and disposal. We continuously adapt them to new technologies and restructure them as necessary to maximise their sustainability.

From rail vehicles and railway workshops to shunting vehicles and track maintenance equipment - our products stand for efficiency, reliability and innovation. WINDHOFF offers you a wide range of market-orientated and high-performance solutions that are ideally suited for your depots as well as for the maintenance and repair of your infrastructure.

Rail vehicles that can be customised to meet all your requirements. With the modular MPV® VentuS®, we have created a modular system that offers you maximum flexibility and has sustainability in mind - a concept that is unrivalled.

We supply customised workshop equipment worldwide - from individual components to the complete equipping of entire depots.

Whether manufacturing, planning or project supervision of complex construction projects - we fulfil every workshop requirement.

When harsh operating conditions demand robust solutions, our shunting technology comes into play.

From simple manoeuvring winches to emission-free, rail-bound Tele-Trac and rail-road shunting vehicles - we cover your entire range of requirements.

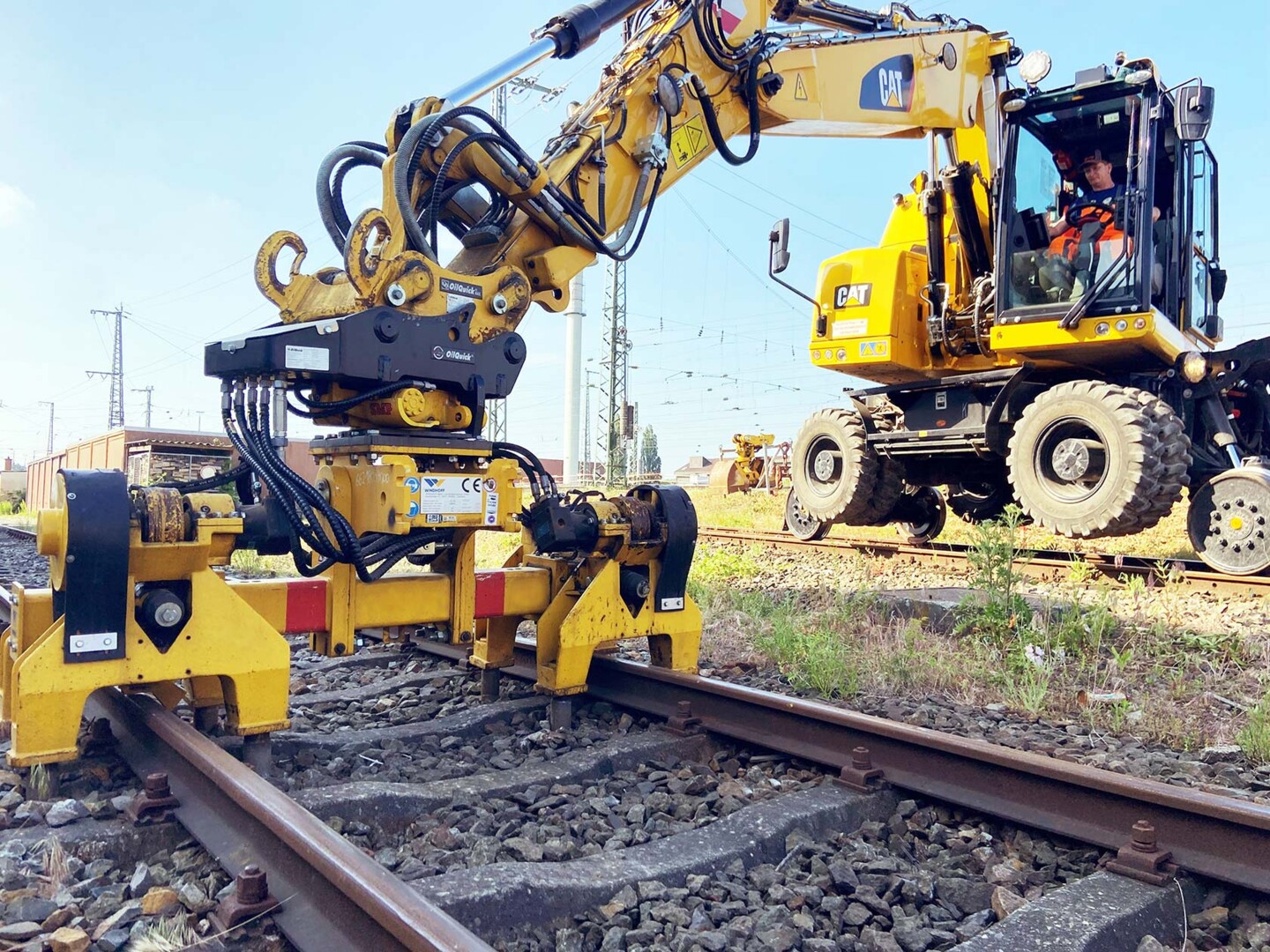

With our comprehensive range of track construction equipment and trailers, we offer the right solution for every requirement - regardless of the industry in which you operate.

Thanks to advanced technology and durable construction, our equipment is ideal for demanding track construction projects.

Sustainability takes centre stage at WINDHOFF. Our innovative and forward-looking solutions not only ensure maximum efficiency, but also sustainable development.

With modular platforms and comprehensive environmental management, we are setting new standards for an environmentally friendly and durable infrastructure.

The ‘Rheiner Maschinenfabrik’ was founded in 1889 by engineer Rudolf Windhoff to develop innovative machines for the emerging railway industry.

On 5 October 1944, the company was completely destroyed by a devastating bombing raid. After the end of the war and the currency reform, the arduous rebuilding of the production facilities began. Despite the initial challenges, the company managed not only to resume production, but also to expand its manufacturing programme. Thanks to major orders from the German Federal Railway, in particular for machines to maintain the superstructure, as well as the expansion of radiator construction, the company developed into a financially stable company again after a short start-up period.

The first climate-neutral depot for DB ICE 4 trains has been equipped, a step towards a more sustainable and environmentally friendly railway infrastructure in Germany.

A new, ultra-modern production hall was built at the Rheine site in order to expand production capacity and integrate state-of-the-art production processes.

In 2022, the first models of the MPV® VentuS® and VentuS®-LR were delivered, marking the start of a new generation of modular and versatile rail vehicles.

52%

179 Employees with completed vocational training and trainees

24%

83 Engineers, bachelors, masters

24%

84 Master craftsmen and technicians

At WINDHOFF, we focus on the highest safety standards and regularly renew our certifications so that all international standards are always met. In this way, we guarantee first-class quality and reliability in rail vehicle production and maintenance.

- ISO 9001, Quality management

- IRIS Rev.04 ( ISO 22163) , Performance Level: Bronze

- ISO 14001, Environmental management system

- SCC, SGU-Managementsystem

- RISQS, Railway Industry Supplier Qualification Scheme

- ISO 3834-2 (Welding certificate)

- EN 15085-2, CL1, field of activity D,P,M,S (Welding of rail vehicles)

- EN 1090-2, EXC3, (Welding certificate)

- Conformity of factory production control up to EXC3 in accordance with EN 1090-2

- DIN EN 17460 (Bonding of rail vehicles and vehicle parts)

- HPQ nach DBS918005 (EXC3 DB)

We are there for our customers, worldwide. Whether for purchase advice, technical support and maintenance or repair and spare parts delivery. With our international service centres, we are always close to you and offer you fast and reliable service.