We use spindle technology to optimise the control of the test forces. The rotary movement of the servomotor is converted into a high-precision linear movement.

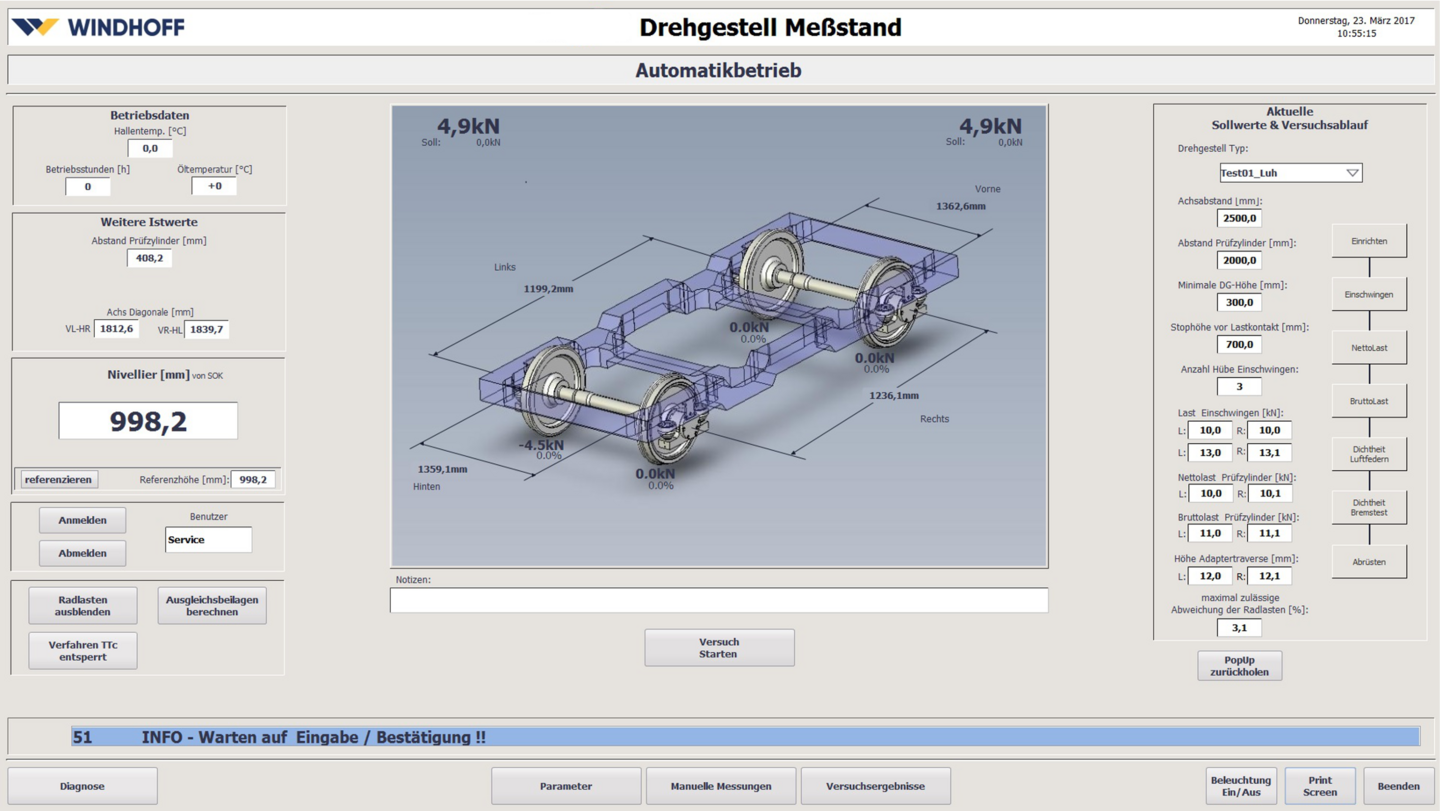

Two electromechanical test cylinders are equipped with vertical position and force measuring devices. This enables efficient testing of wheel load distribution for a wide range of bogie types and loads.

Other measuring tasks include checking centre distances, wheel back distances and various bogie installation dimensions. Our measuring stands are equipped with position measuring systems, force transducers, load cells and pressure sensors.

High-precision measuring amplifiers ensure precise results. We only use components from well-known manufacturers. The automatic centre centring of the high-speed test stands guarantees the best measurement results and high repeat accuracy.

Thanks to our modular design, we can offer a wide range of additional equipment that is precisely tailored to our customers' requirements, and these modules can also be retrofitted at a later date. The closed power frame allows installation on the hall floor or in a foundation pit.

The bogie test stand offers comprehensive visualisation and meaningful report printing. The user-guided operation takes you step by step through the defined test sequence. All measured values are displayed on the screen in real time. We provide the results in a separate file for evaluation by other QM systems.

Whether you need personalised advice or have a special request - we are at your side. Please use our contact form to send us your enquiry. Our team will get in touch with you as soon as possible to provide you with the best possible support.