Modular design for maximum flexibility: an overview of the MPV® VentuS® modular system

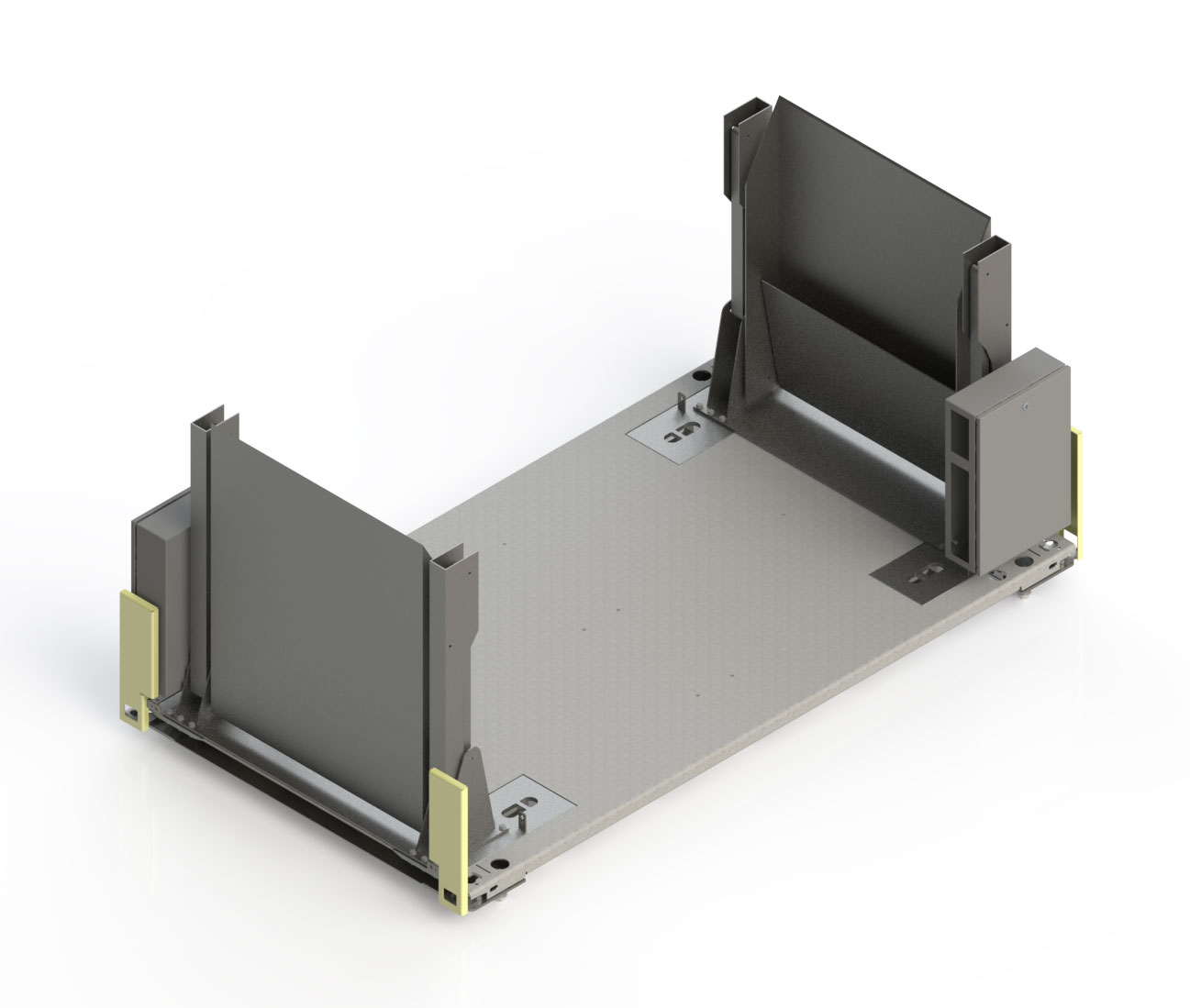

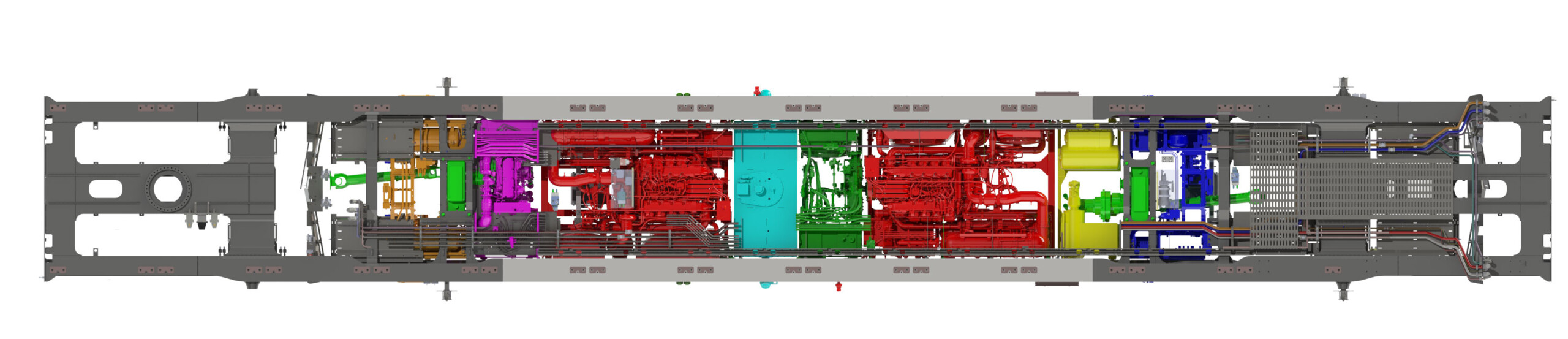

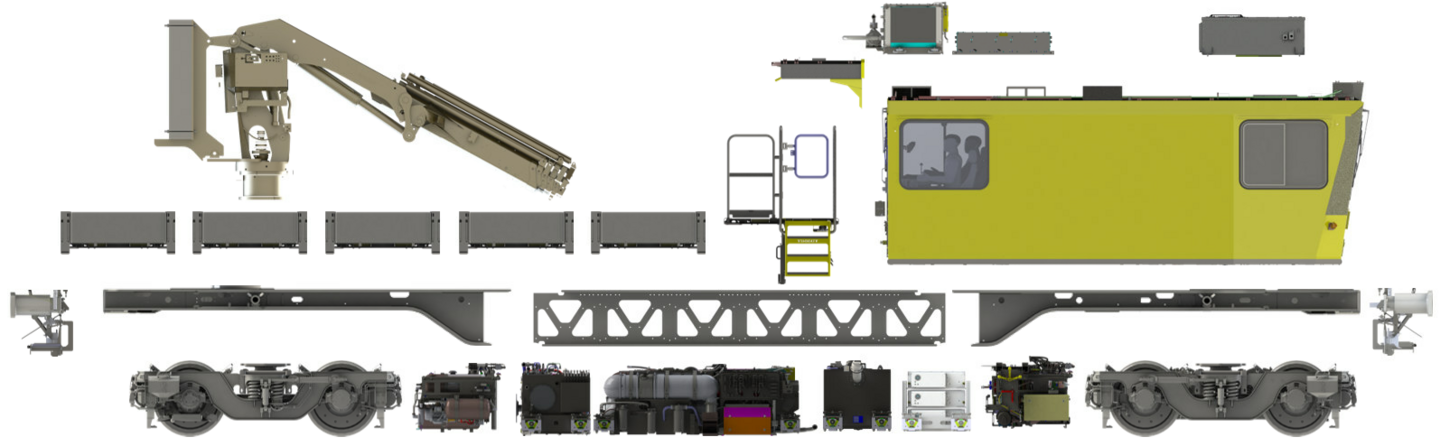

Not only is the vehicle's drivetrain, which is located in the vehicle frame undercarriage, modular in design, but also work equipment, such as cranes or platforms, as well as vehicle modules, such as the vehicle frame and the cabs themselves. Installation spaces and interfaces are clearly defined, making each module self-contained.

The result is a modular system that is variable and expandable in terms of vehicle length, type of implement, drive system and intended use - in short: modular.

The MPV® VentuS® is designed on the basis of DIN EN 14033-1 to -3 and is TSI-approved. In addition to the requirements from the TSI, additional national requirements, the NNTRs, of the respective area of use are taken into account. Our approval strategy and the modular system are closely linked.

‘The MPV® VentuS®’ does not exist in this sense. Thanks to extensive advance development of this ‘modular system’ MPV® VentuS®, a wide variety of vehicle configurations are possible by combining different modules from the MPV® VentuS® module portfolio. The minimum vehicle length over buffers can be approx. 16,500 mm and the maximum vehicle length approx. 22,500 mm.

The route classes that can be travelled depend on the desired payload to be carried and the mass of the vehicle configuration itself. Reference projects have already confirmed the drivability of route class A including the relevant payload.

To date, WINDHOFF has approved over 100 vehicles with ETCS, which over time has led to the development of significant expertise in this complex system in Rheine. In addition to the current ETCS 3.6.0 L2, national or route-specific train control systems can also be flexibly integrated.

On the one hand, the cabin modules have different lengths, but can also be designed to be unidirectional or bidirectional.

The conversion of implements can be realised as well as the expandability and interchangeability of drive modules. The strictly predefined interfaces of the overall system are used specifically for this purpose.

The modular solution for mainline railways

MPV® VentuS® highlights

Our flyer contains comprehensive information on equipment, areas of application, drive concepts and registration options.

Maximum flexibility, emission-free drive concepts and cross-border registration – download all the details of the MPV® VentuS® as a PDF file.

Whether you need personalised advice or have a special request - we are at your side. Please use our contact form to send us your enquiry. Our team will get in touch with you as soon as possible to provide you with the best possible support.

Martin Kühnhenrich

Head of Sales and Project Management Rail Vehicle Technology