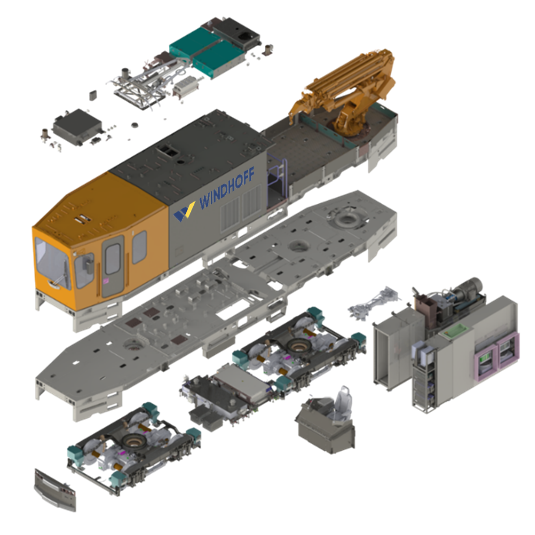

Modular design for maximum adaptability in urban rail: MPV® VentuS®-LR at a glance

The rail grinding vehicle, on the other hand, has been specially developed for preventive grinding work and cleaning rails. It enables low-noise work with minimal impact on the surrounding area and ensures smooth operation in the urban rail network. Both vehicle types stand for flexibility, efficiency and adaptability in order to meet the specific requirements of urban rail systems.

Our rail and track maintenance vehicles for urban transport are approved on the basis of the relevant national and international standards, such as the BOStrab (Ordinance on the Construction and Operation of Trams) or EN 14033. This approval takes into account the specific requirements of urban rail transport.

Our vehicles can be equipped with various train control systems that are tailored to the requirements of urban rail transport. This includes systems such as BOStrab-compliant safety and signalling technology that ensure smooth and safe operation in cities.

Yes, the rail towing vehicle is bidirectional and can therefore be operated in both directions. This increases flexibility and efficiency when used in urban rail networks.

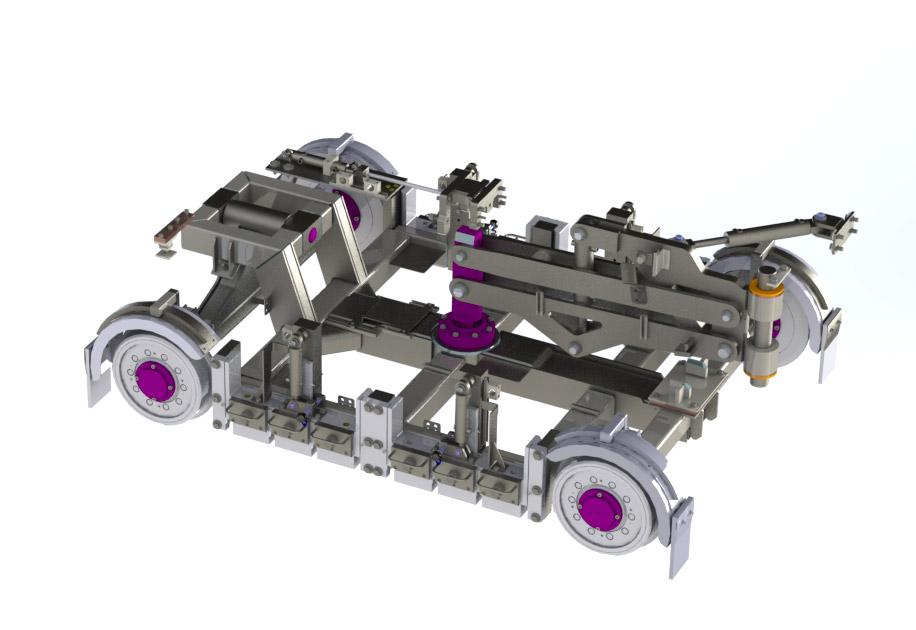

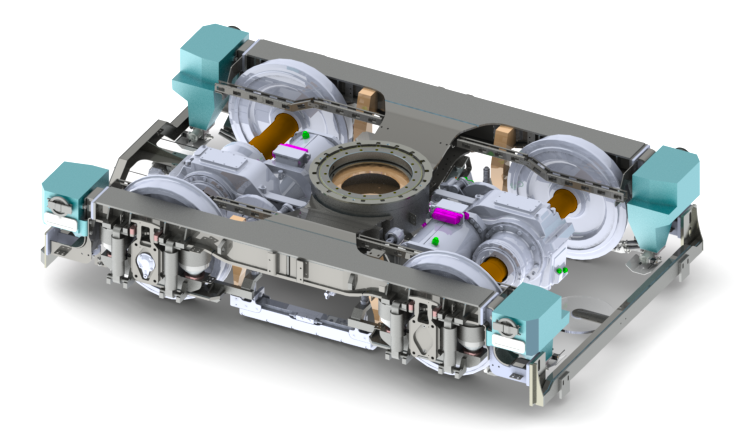

Yes, the track maintenance vehicle has a modular system that makes it easy to convert. For example, crane equipment can be replaced with working platforms or other modules to enable the vehicle to be used flexibly for different tasks throughout its service life.

THE FLEXIBLE VEHICLE SOLUTION FOR urban & Light rail

MPV® VentuS®-LR Highlights

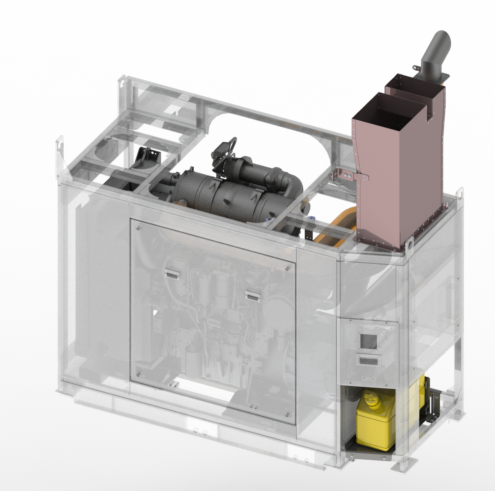

The MPV® VentuS®-LR offers the ideal platform for municipal operators and local transport companies. Whether for shunting, maintenance or construction, the modular concept enables tailor-made vehicle solutions for everyday requirements in urban areas.

Future-proof drive systems, flexible equipment and high approval reliability – discover all the details in our PDF flyer.

Whether you need personalised advice or have a special request - we are at your side. Please use our contact form to send us your enquiry. Our team will get in touch with you as soon as possible to provide you with the best possible support.

Martin Kühnhenrich

Head of Sales and Project Management Rail Vehicle Technology