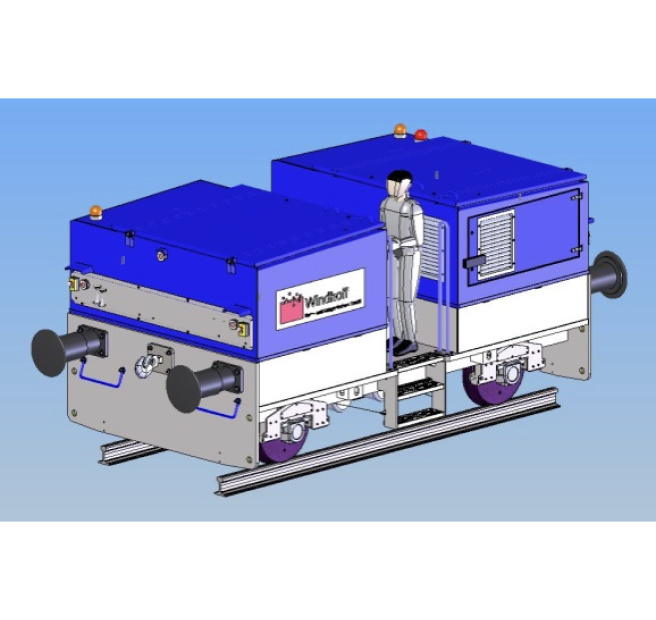

The basic concept of the RW TeleTracs was created in 2014 and has been continuously developed and optimised. The design is based on robust rail vehicles. Railway-specific requirements for fatigue strength, frame stability (suitable for buffer impact), coupling systems, track guidance, compressor system, radio remote control, etc. were taken into account during development.

The vehicles can be approved in Germany in accordance with the BOA (Ordinance on the Construction and Operation of Railway Sidings). Further country-specific authorisations are optionally available.

Additional compressors for wagon braking, automatic couplings, sanding, wheel flange lubrication or cabins are available on request. They are ideal for integration into fully automatic shunting or loading/unloading processes. The vehicles have a remote maintenance module with full access to the SIEMENS PLC programme. Log data such as compressor operating hours can also be read out.

Flexible use on company premises and in halls.

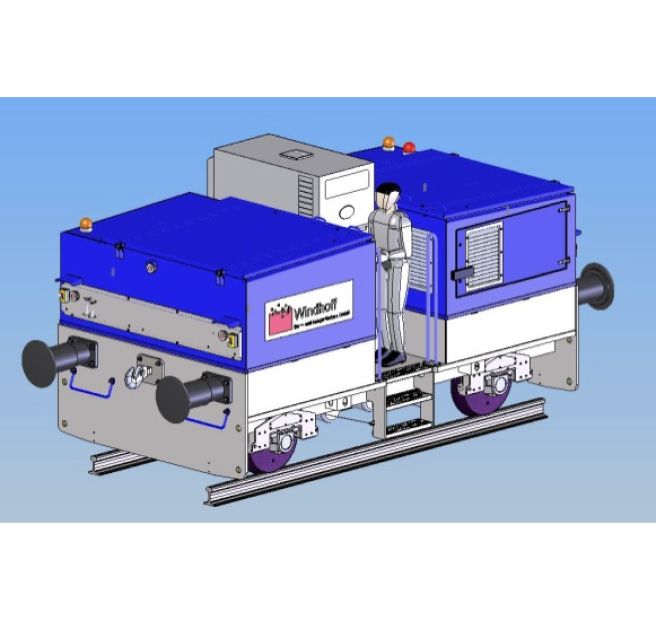

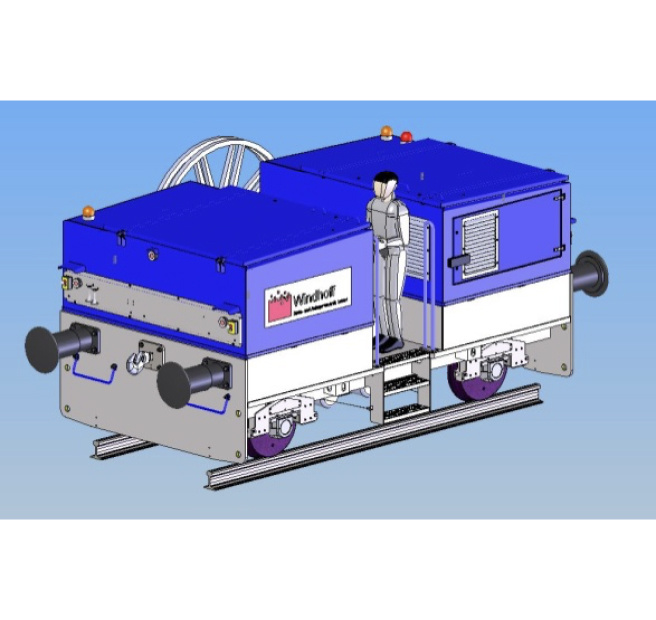

Lead or lithium batteries are used, battery changing systems are also available. The battery is charged via a CEE plug connection, contactless inductive charging or via a conductor rail.

Flexible use on company premises and in halls.

Multi-shift use possible.

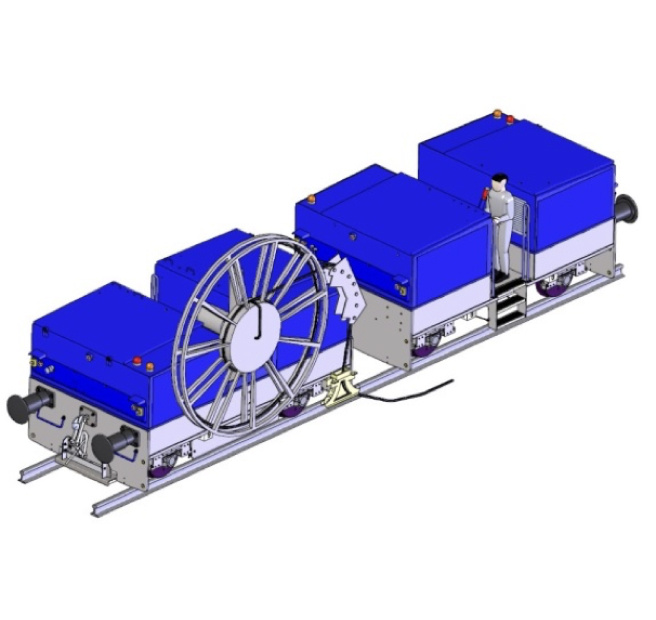

Power supply via cable drum. Use in limited operating area.

Multi-shift use, without interruption.

Tractive force multiplication depending on the number of coupled traction units.

Hydraulically driven and lowerable road running gear is attached to the front ends of the TeleTrac. The shunting vehicle can be raised at a defined point (e.g. at concreted points with track support plates) and moved sideways across the track.

The advantage is that this ‘two-way’ functionality frees up the track for other locomotives, wagons etc. and can be used as a through track.

Our rail-bound shunting vehicles combine reliability, robustness and environmental friendliness. Specially developed for internal shunting and loading tasks, our product range is divided into three main groups that are tailored to different requirements and areas of application.

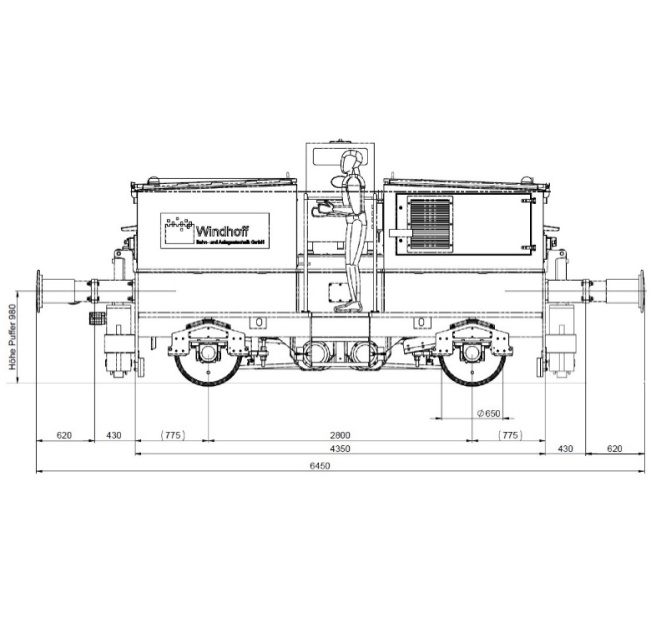

The RW is the price-performance winner with high driving force requirements at low speed. It is characterised by its robustness and use under extremely difficult environmental conditions.

This product is used from a trailer load of >500 tonnes, with multiple traction up to 13,000 tonnes.

The shunting locomotives are used at slightly higher speeds, guide value 9-12km/h to max. 40km/h. Tractive forces of 60kN to 120kN can be realised with this product. Towing load >1000t, with multiple traction even significantly more.

In the special vehicles segment, Windhoff impresses with all kinds of customised adaptations.

Be it specially equipped shunting vehicles with, for example, heat protection for use under extreme environmental conditions, or other special customer adaptations.

Curious about what is possible?

Whether you need personalised advice or have a specific request - we are here to help. Please use our contact form to send us your enquiry. Our team will get in touch with you as soon as possible to provide you with the best possible support.