From train protection systems and drive concepts to complete packages. We modernise your vehicle comprehensively across all areas.

- ETCS

- Original equipment for new vehicles

- Retrofitting existing vehicles and third-party vehicles

- Upgrades (baseline)

- Modernisations

- Crane / work platform

- Drive concept (engines, fuel cell for hydrogen drive, electrification)

- Exhaust gas aftertreatment

- Winter equipment (snow brush, snow plough, etc.)

- Workshop equipment

- Control system (PLC)

- Sander bogie

- Repainting

- Vehicle modernisation

Modularisation MPV® VentuS®

- Project planning and development

- Certified quality management system ISO 9001

- IRIS certification according to ISO/ TS 22163

- Authorisation

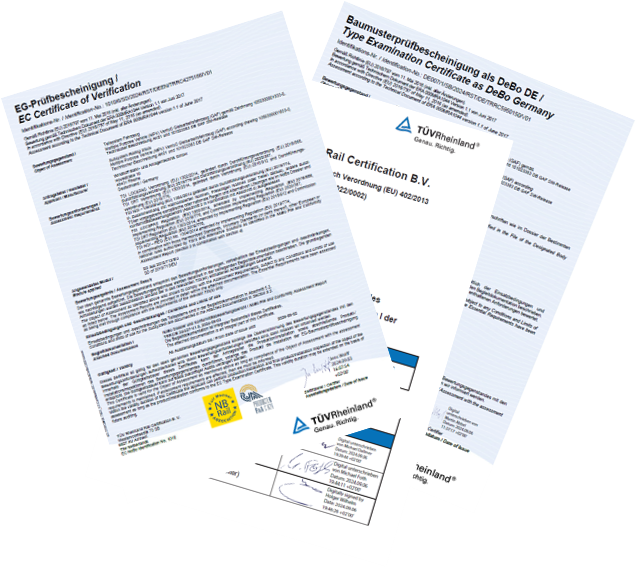

Process reliability in the 4th railway package incl. national requirementsApproval for your use within Europe

- Manufacturing and system integration

- Certified welding expertise in accordance with DIN EN 15085

- Certified bonding expertise in accordance with DIN 6701

- Certified production control according to EN 1090

- Q1 supplier for the MPV® VentuS® type DB GAF

- Environmental management system according to ISO 14001

Modernisation can have many decisive causes: New work packages that require different vehicle equipment, new environmental requirements that demand, for example, better exhaust aftertreatment or even new drive concepts, new route sections that are equipped with ETCS, for example, and the vehicle needs to be retrofitted or upgraded with ETCS.

A retrofit ensures that your vehicle remains fully usable in the future and maximises its service life.

We have an open ear for you and communication is the key to our success. Direct contact with the customer is a top priority for us right from the start.

Brainstorming is essential in order to be able to respond to your wishes and requirements in the best possible way. This is the only way we can draw on all our experience and offer you the best possible solution for your project.

The conceptualisation and development of your project is carried out here at our location in Rheine. After brainstorming, the next step is to realise the ideas and get the project up and running. Short decision-making paths are very important to us and can only be achieved by our own internal development and design department.

As part of a ‘ready to use’ retrofit, this also includes accompanying the entire approval process and successfully completing it. Be it the approval by EBA or TAB or the consideration of product safety. Our Authorisation & Product Safety team is involved in all phases right from the start. In this way, we ensure that we are able to overcome any potential challenges right from the brainstorming stage.

Our experienced production team masters every project. In our retrofit and refurbishment hall, we have everything you need for modernisation. Equipped with tracks and lifting jacks as well as two crane bridges, each with two trolleys and a total payload of 40 tonnes each, we are equipped for all project phases.

The conversion is followed by commissioning. Depending on the project, this is carried out by our colleagues in production, in cooperation with our design department or external service providers. Test runs in standard gauge up to 50 km/h are also no problem on the nearby test track and are part of our commissioning process, as is the training of operators and, on request, maintenance personnel, which is an essential part of our final project phase. These are either carried out directly on site or held as theory sessions in training rooms. Find out more about our training courses here.

We also support you after the final handover. Be it the supply of spare parts according to maintenance intervals, the realisation of the individual intervals on your premises or long-term support through an exclusive maintenance contract. When the project ends, our support begins. Get in touch with us!

Let us know about your ideas and together we can discuss possible solutions and work out solutions.